Scragg Mills

The HELLE Scragg Mill

- Overhead end dogging really pumps out the ties, cants and flitches

- High production of the products that are in big demand

- Competitively priced

- Now available with scanning

- Shave the edging strips into shavings or chips!.

- Computer controlled setworks giving the control and accuracy for tight tolerances!

- Works With The Scanning Package, achieve edged slabs for resaws or a board!

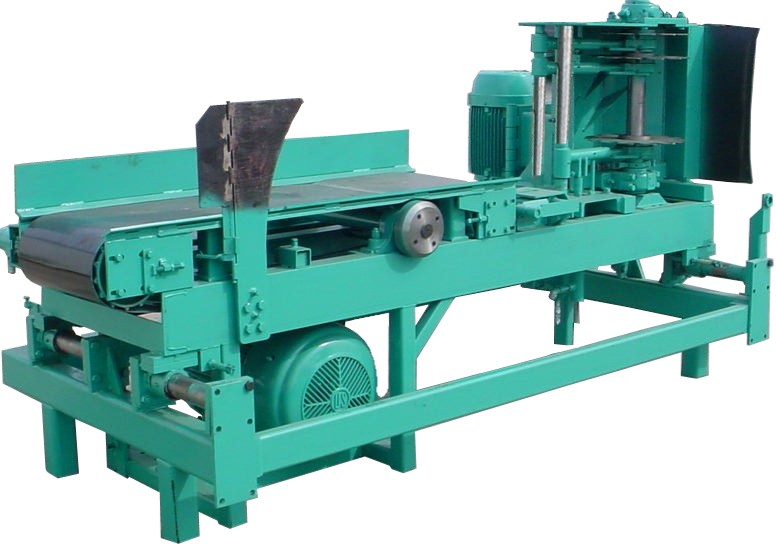

HELLE Scragg Husks

HELLE Scragg With Shaver Heads

HELLE Scragg With Vertical Edgers

Helle Scragg With Chain Cant Seperation/Slab Dump

SCRAGG MILL FEATURES

- Fast Processing of logs 4′ To 12′ (18′ & 20′ Optional)

- Scanning System Automatically Positions The Log And Saws

- Diameters Of 4 to 16”, 4 to 24”, and The Monster: 4 to 30”!

- Hydrostatic Carriage Feed

- All Electric Over Hydraulic Controls, Which Means:

- No Manual Valves

- No Oil Lines To The Saw Cab

- No Noise In The Cab!

- Self contained hydraulic system on the carriage, no oil lines on the pantograph.

- Computer controlled setworks giving the control and accuracy to cut grade off BOTH sides, in one pass!

- Superior design in clamping and positioning to give you the BEST in control.

- Cant Transfers and Drop Belt for fast reliable sorting and transferring of the finished product and slabs

- Optional Independent Husk Control

Integrated Vertical Edgers

- Available In 2 or 3 Saw

- 30 to 75 HP

- 22” or 24” Blades

- Split or Inserted Tooth Blades

- 2 15/16” TGP Mandrel

- Heavy Duty Bearings